Are you considering installing metal roofing yet worried about the costs involved? You’re not alone—many homeowners and builders seek ways to minimize expenses while ensuring quality. This comprehensive guide will provide you with invaluable insights on how to save money when installing metal roofing materials. From understanding how to choose cost-effective materials to evaluating different manufacturers for better pricing, we’ll cover all the essential steps. You’ll learn how to strategically plan your installation budget, leverage manufacturer discounts, and even explore DIY techniques that can significantly reduce costs. By the end of this article, you’ll be equipped with the knowledge to make informed decisions and maximize your savings, all while enhancing the durability and aesthetic appeal of your property. Let’s dive in!

Understanding How To Choose Cost-Effective Metal Roofing Materials

Choosing cost-effective metal roofing materials involves a thoughtful approach to ensure both quality and affordability. Here are some key factors to consider:

- Material Type: Different metal roofing materials, such as steel, aluminum, or copper, come at varying price points. Steel is generally the most cost-effective option, while copper can be significantly more expensive. Assess your budget and needs to select the most suitable material.

- Gauge Thickness: The thickness of the metal affects its durability and cost. A thicker gauge offers better longevity and weather resistance but may come at a higher price. Weigh the long-term benefits against initial costs to determine the best option for your situation.

- Finish and Coating: Coated or painted metal panels may have higher upfront costs but provide additional protection and energy efficiency. Evaluating the lifecycle costs can help in deciding whether the initial investment is justified.

- Source and Manufacturer: Research various manufacturers to find competitive pricing. Some manufacturers may offer deals or discounts for bulk purchases, which can lead to substantial savings.

- Local Availability: Sourcing materials locally can help reduce transportation costs. Check with local suppliers to find affordable options, and consider any warranties or services they might offer as added value.

By carefully assessing these factors, you can effectively determine how to choose cost-effective metal roofing materials that meet your budget while ensuring quality and durability for your roofing project.

How To Evaluate Different Manufacturers For Better Pricing

When looking to save money on your metal roofing installation, evaluating different manufacturers is crucial. This process allows you to compare products, pricing, and overall value, ensuring that you get the best deal without compromising on quality. Here’s how to go about it:

By following these steps, you can effectively evaluate different manufacturers and make informed decisions that align with your budget and quality expectations. This diligent approach will enable you to find the best pricing options while ensuring the long-lasting performance of your metal roofing materials.

Steps To Plan Your Metal Roofing Installation Budget

When it comes to installing metal roofing, careful financial planning is essential to ensure that you stay within your budget without compromising on quality. Here are some detailed steps on how to effectively plan your metal roofing installation budget:

1. Assess Your Roofing Needs: Begin by evaluating the size and slope of your roof. This will help determine the amount of materials you will need. Measure the roof area to get precise calculations.

2. Research Material Costs: Research different metal roofing materials, such as aluminum, steel, or copper, and gather estimates from various suppliers. Use a how to approach to compare the costs effectively. Create a spreadsheet for easy comparison.

3. Account for Additional Supplies: Don’t forget to include additional materials like underlayment, flashing, and ventilation systems. These can significantly impact your overall costs.

| Item | Estimated Cost |

|---|---|

| Metal roofing panels | $3 – $7 per square foot |

| Underlayment | $0.50 – $1.00 per square foot |

| Flashing | $2 – $4 per linear foot |

| Ventilation | $1 – $3 per square foot |

4. Consider Labor Costs: If you’re hiring professionals, obtain quotes for labor. Plan for installation costs, which can depend on your region and the complexity of the job. This adds another layer to your budget considerations.

5. Include Contingency Funds: It’s wise to set aside 10-20% of your total budget for unexpected expenses. This precautionary measure can prevent any financial strain during the installation process.

6. Explore Financing Options: Look into financing options or roofing loans if upfront costs seem daunting. Some suppliers may offer payment plans as well.

7. Review Your Budget Regularly: As the project progresses, regularly monitor your expenses against your budget. This will help you adjust as needed and ensure that you stick to your financial plan.

8. Final Approval and Execution: Once everything is finalized, review your budget and make any necessary adjustments. Ensure that all costs are covered, and you feel comfortable moving forward with the installation.

By following these structured steps on how to plan your metal roofing installation budget, you can gain better control over your finances and make informed decisions, ultimately ensuring a smoother installation process.

How To Leverage Discounts From Metal Roofing Material Manufacturers

Finding the best prices on metal roofing materials can significantly impact your project budget. Here are some strategies on How To leverage discounts effectively from manufacturers:

- Research Promotions and Discounts: Monitor manufacturer websites and subscribe to newsletters to stay informed about seasonal promotions or special discounts. Many companies offer sales during the off-season or specific holidays.

- Bulk Purchase Discounts: If you’re renovating or constructing multiple structures, consider buying in bulk. Many manufacturers provide substantial price reductions for large orders.

- Negotiate Pricing: Don’t hesitate to negotiate with suppliers. Many are willing to offer discounts, especially for contractors or larger orders. Building a good relationship with your supplier can also help in gaining better deals in the future.

- Promotional Coupons: Look for coupons or special offers provided by manufacturers or their distributors. These can often be found online or through industry publications.

- Utilize Trade Shows: Attending trade shows can present opportunities to meet manufacturers directly, and many times, attendees get exclusive discounts or samples that can lead to lower costs.

- Check for Referral Programs: Some manufacturers have referral programs that reward you for bringing new customers. This can lead to discounts on your future purchases if you can refer others to them.

By applying these strategies, you can save a considerable amount on your metal roofing project while ensuring quality materials from reputable manufacturers.

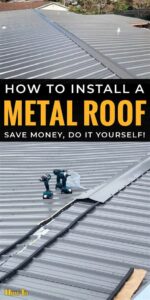

Maximizing Savings Through DIY Metal Roofing Installation Techniques

One of the most effective ways to save money when installing metal roofing is by considering a DIY approach. With proper planning and the right tools, you can significantly cut labor costs while ensuring quality work. Here are some techniques to help you maximize savings:

- Research and Preparation: Before starting your installation, make sure to thoroughly research metal roofing materials and installation techniques. Online tutorials, videos, and forums can provide valuable insights.

- Gathering Tools: Ensure you have all the necessary tools on hand. This typically includes safety gear, measuring equipment, power tools, and fastening tools. Investing upfront into quality tools can save you money in the long run.

- Installing During Off-Peak Seasons: If you’re flexible with your project timeline, consider scheduling your installation during off-peak seasons when suppliers might offer lower prices and more availability.

Additionally, practical techniques such as:

| Technique | Description |

|---|---|

| Modulo Installation | Use prefabricated panels that are easier to handle and install, allowing for faster installation times. |

| Recycling Old Materials | If replacing existing roofing, consider recycling or repurposing materials which can reduce disposal costs. |

Don’t forget to tap into community resources. Many neighborhoods have DIY groups where members share knowledge and possibly tools. This can not only aid your installation process but also help you save on equipment costs. Following these practical steps can help you learn how to efficiently install your metal roofing and keep your overall expenses low.

Frequently Asked Questions

What are the benefits of choosing metal roofing over traditional roofing materials?

Metal roofing offers durability, longevity, energy efficiency, and low maintenance costs, making it a cost-effective choice over time.

How can I save money on metal roofing installation?

Consider purchasing roofing materials during off-seasons, shopping around for quotes from different contractors, and exploring DIY installation options if you have the skills.

Are there specific types of metal roofing that are more economical?

Steel panels and aluminum roofing are typically more affordable options compared to copper or zinc, while still providing excellent durability.

What should I look for in a metal roofing manufacturer?

Look for manufacturers with a strong reputation, good warranties, quality certifications, and positive customer reviews to ensure you are getting reliable materials.

Can I negotiate prices with roofing contractors?

Yes, it’s often possible to negotiate prices, especially if you have multiple estimates or if you choose to do some work yourself.

What other costs should I consider beyond the metal roofing material?

Don’t forget to factor in costs for underlayment, flashing, fasteners, insulation, and disposal of old roofing materials.

How does local climate affect the selection of metal roofing materials?

Select roofing materials based on climate conditions; for example, stainless steel may be chosen for coastal areas to resist corrosion, while lighter colors can reduce heat absorption in hot climates.